on this page

-

Markets

Transportation

-

Location

UK

Digital Image Correlation (DIC) is a revolution in the ability of engineers to see and understand how structures are performing in service without the cost, time and disruption traditional methods usually require.

The ongoing cost of maintaining the world’s physical infrastructure is staggering. Take bridges alone: it’s estimated that some £70bn is spent annually on repairing bridge structures that have deteriorated under loads and environmental conditions, to the stage where expensive reactive maintenance is required. Caught early, less expensive interventions can often be implemented.

Traditionally, one way to detect deterioration has been to measure how structures are deflecting and straining and compare this with analytical model predictions. For example, a bridge deck deflecting more than it should, might indicate a loss of stiffness from corrosion or even an inherent design problem. However, conventional techniques to collect this information use bulky equipment requiring surface contact and partial or full closures to road or rail traffic.

The award-winning Digital Image Correlation (DIC) capability developed by AtkinsRéalis is a quick and flexible method that enables assessments to be made of localized areas or entire structures. It can provide either a short-term snapshot of an asset’s performance or periodic insights over time.

We use various types of cameras ranging from CCTV, drone-mounted and smartphones to collect and interpret the measurement data and generate the necessary insights. The imagery captured by our cameras can pick out detail to the pixel, enabling us to measure movements and deflections to a fraction of a millimeter. We can work out stress in an element based on its displacement, determine fatigue risk in sensitive elements under cyclic load, and ultimately, we can see how a structure is behaving at any given time.

The ability to remotely monitor structures by simply setting up a camera also gives a threefold safety improvement:

- There is no need for operatives to physically install equipment in hazardous areas.

- The ease of use means it can be used more often and faster to check structures that are a cause for concern

- The results give us detailed knowledge of true structural performance, giving confidence to asset owners.

Bridges: DIC reveals more than the eye can see

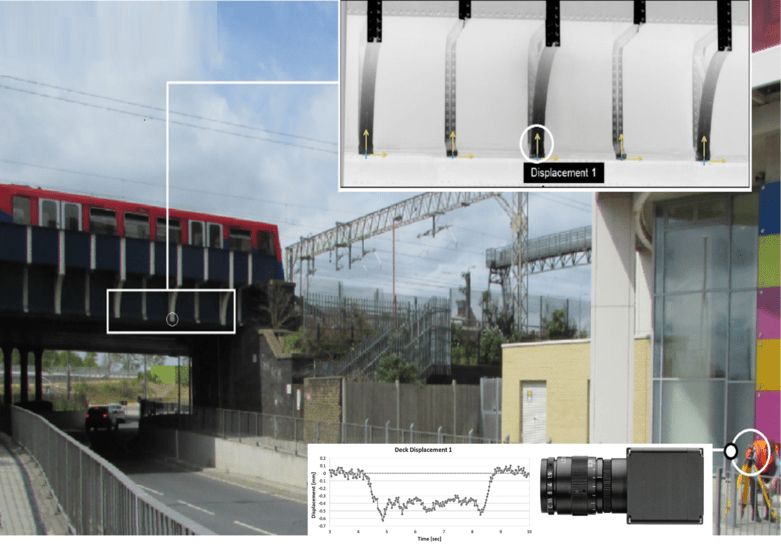

We are already realizing significant savings for clients through improved structural understanding. On the Docklands Light Railway (DLR) in London, our client was expanding trains from two to three cars and wanted to assess its bridge stock for the resulting 50% increase in traffic. Initial structural calculations concluded that significant strengthening would be needed to several bridges to provide adequate fatigue life, involving significant expenditure plus disruption to the network. However, AtkinsRéalis was able to show that the real stresses in the bridge were lower than predicted.

Using a camera positioned 60 meters away, we monitored both the vertical deflection and peak strain on the bottom of the deck. This assessment revealed that the stress range under trains was 40% less than had been indicated by the computer modelling, owing to the presence of previously unmodeled concrete tension stiffening. This entire exercise was carried out in a single day, with no traffic disruption – and demonstrated that no strengthening of the bridge was needed.

We have many use cases for DIC in the UK, such as:

- The French Horn Bridge, Salisbury: DIC has been used to monitor bearing rotation and deck displacementt, showing that intervention was not required.

- The Humber suspension bridge, Hull: used to monitor performance of the hangers and deck. Hanger replacement was also verified using DIC to show the deflections from non-linear models matched with measurements taken on site.

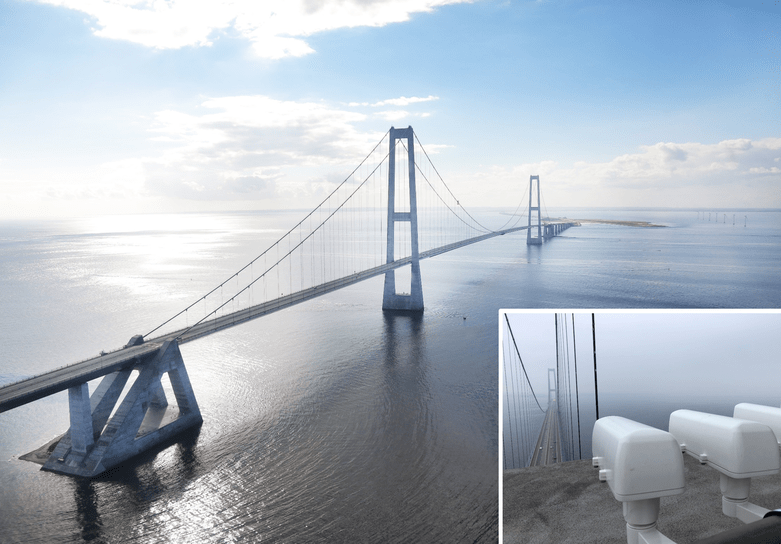

Outside the UK, our other DIC projects have included a combination of long-term monitoring of expansion joint movements due to temperature, and permanent monitoring of hanger movements due to wind and traffic load.

For the Great Belt Suspension Bridge in Denmark, DIC was used to validate questionable accelerometer readings. Improved data quality from measurement of wind-induced hanger vibration, traffic-induced deck deflection and temperature-induced expansion joint movement has given our client a better understanding of bridge performance and has informed and enhanced their bridge fatigue management strategy.

Rail: DIC revolutionizes OLE understanding

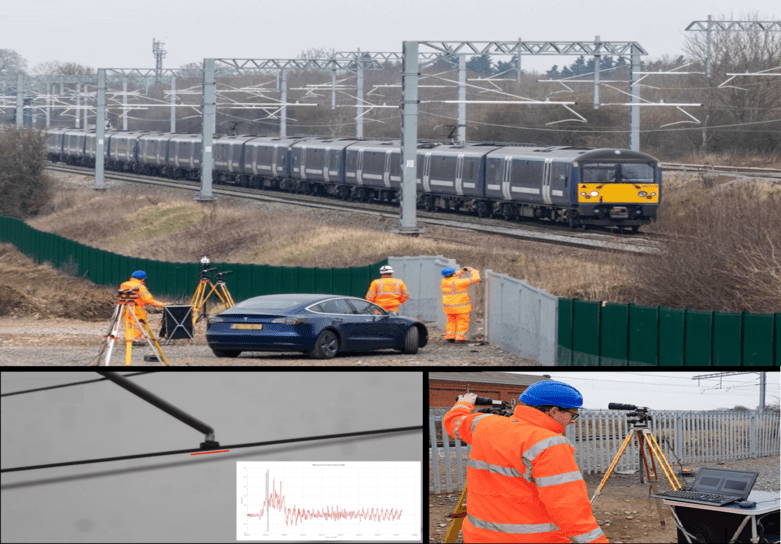

Network Rail was looking to develop nationwide rules for Overhead Line Equipment (OLE) designers to reduce the required clearance between OLE equipment and overbridge soffits. The joint AtkinsRéalis team (Rail & SHM DIC) were responsible for completing the first large-scale project to measure OLE uplift at overbridges across the UK. On completion of the project, the Rail team recommended that the existing uplift design value could be reduced for all bridge arms, enabling multimillion cost savings across the nation on future electrification schemes. The success of this project led to a further contract looking at open route uplift to assess clearances to structures, signalling equipment and free-running bridges.

The current project provides statistical analysis of over 1600 train passages measured at 10 sites which cover a range of criteria including different OLE structure types. The DIC team successfully monitored 3 points per train pass - the midspan catenary wire, contact wire and registration arm in both directions. The joint AtkinsRéalis team overcame logistical, data storage and results processing challenges throughout the project. Leadership from the rail team was supplemented by efforts from the SHM DIC engineers to meet client expectations

On completion of the project, the Rail team recommended that the current clearance uplift in designs can be reduced for certain equipment, enabling multi-million pound cost savings across the nation on future electrification schemes.

“The uplift monitoring project has revolutionised how we understand the dynamic performance of OLE at bridges. This has allowed us to reduce the space required for electrification. The findings from this project have already been incorporated into our design standards and will reduce the number of bridge reconstructions. The impact of this will save millions of pounds, reduce disruption to passengers, and reduce embedded carbon as we electrify the railway.” Richard Stainton, Network Rail

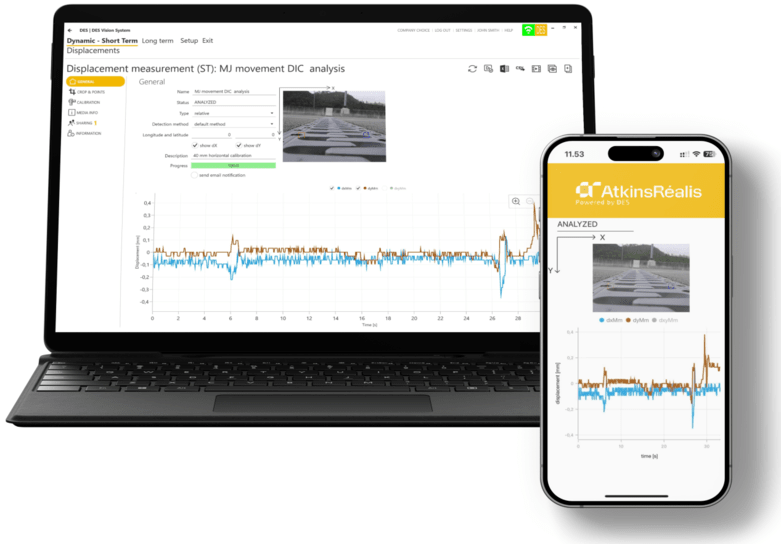

An accessible mobile app to transform structural data

Up till now, DIC inspections have required specialist equipment and training, which is costly and time-consuming. In collaboration with high-tech startup Digital Engineering Solutions (DES), AtkinsRéalis has enhanced its DIC capability via an easy-to-use mobile app.

Our engineers can quickly and easily capture and analyze structural data using the app, enabling faster, more accurate and more efficient results.

AtkinsRéalis has already deployed mobile DIC monitoring on a number of structures including the Grosvenor Bridge in London, the Marlow Suspension Bridge in Buckinghamshire, the Newport Bridge and the Transporter Bridge in Middlesbrough. In each case, we demonstrated that smartphone-based tools are potentially game-changing with respect to structural health monitoring (SHM) and asset condition reporting, enabling engineers to capture and analyze structural displacements with mm-accuracy, making previously unavailable data more accessible and delivering added value for clients.

Helping inform our clients of potential service life extension enables them to maximize the useable life of an asset. This also helps reduce their potential carbon footprint, simply by building less.

Summary

The use of DIC gives asset owners affordable and accurate analysis of real structural performance and is a huge step forward in improved structural asset management. It has the potential to give engineers clear data on how the structure is performing in service, regardless of complexity or hidden load paths and helps validate information from models or other instruments.

Please note that you are now leaving the AtkinsRéalis website (legal name: AtkinsRéalis Group inc.) and entering a website maintained by a third party (the "External Website") and that you do so at your own risk.

AtkinsRéalis has no control over the External Website, any data or other content contained therein or any additional linked websites. The link to the External Website is provided for convenience purposes only. By clicking "Accept" you acknowledge and agree that AtkinsRéalis is not responsible, and does not accept or assume any responsibility or liability whatsoever for the data protection policy, the content, the data or the technical operation of the External Website and/or any linked websites and that AtkinsRéalis is not liable for the terms and conditions (or terms of use) of the External Website. Further, you acknowledge and agree that you assume all risks resulting from entering and/or using the External Website and/or any linked websites.

BY ENTERING THE EXTERNAL WEBSITE, YOU ALSO ACKNOWLEDGE AND AGREE THAT YOU COMPLETELY AND IRREVOCABLY WAIVE ANY AND ALL RIGHTS AND CLAIMS AGAINST ATKINSRÉALIS, AND RELEASE, DISCHARGE, INDEMNIFY AND HOLD HARMLESS ATKINSRÉALIS, ITS OFFICERS, EMPLOYEES, DIRECTORS AND AGENTS FROM ANY AND ALL LIABILITY INCLUDING BUT NOT LIMITED TO LIABILITY FOR LOSS, DAMAGES, EXPENSES AND COSTS ARISING OUT OF OR IN CONNECTION WITH ENTERING AND/OR USING THE EXTERNAL WEBSITE AND/OR ANY LINKED WEBSITES AND ANY DATA AND/OR CONTENT CONTAINED THEREIN.

Such waiver and release specifically includes, without limitation, any and all rights and claims pertaining to reliance on the data or content of the External Website, or claims pertaining to the processing of personal data, including but not limited to any rights under any applicable data protection statute. You also recognize by clicking “Accept” that the terms of this disclaimer are reasonable.

The information provided by Virtua Research cited herein is provided “as is” and “as available” without warranty of any kind. Use of any Virtua Research data is at a user’s own risk and Virtua Research disclaims any liability for use of the Virtua Research data. Although the information is obtained or compiled from reliable sources Virtua Research neither can nor does guarantee or make any representation or warranty, either express or implied, as to the accuracy, validity, sequence, timeliness, completeness or continued availability of any information or data, including third-party content, made available herein. In no event shall Virtua Research be liable for any decision made or action or inaction taken in reliance on any information or data, including third-party content. Virtua Research further explicitly disclaims, to the fullest extent permitted by applicable law, any warranty of any kind, whether express or implied, including warranties of merchantability, fitness for a particular purpose and non-infringement.

The consensus estimate provided by Virtua Research is based on estimates, forecasts and predictions made by third party financial analysts, as described above. It is not prepared based on information provided by AtkinsRéalis and can only be seen as a consensus view on AtkinsRéalis' possible future results from an outside perspective. AtkinsRéalis has not provided input on these forecasts, except by referring to past publicly disclosed information. AtkinsRéalis does not accept any responsibility for the quality or accuracy of any individual or average of forecasts or estimates. This web page contains forward-looking statements based on current assumptions and forecasts made by third parties. Various known and unknown risks, uncertainties and other factors could lead to material differences between AtkinsRéalis' actual future results, financial situation, development or performance, and the estimates given here.

Downloads

Trade releases